- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

Titanium anode for treating papermaking black liquor

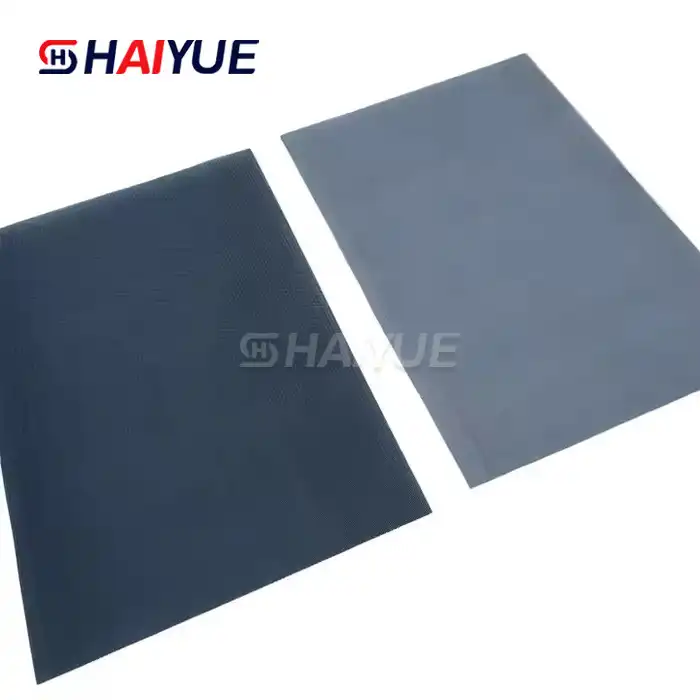

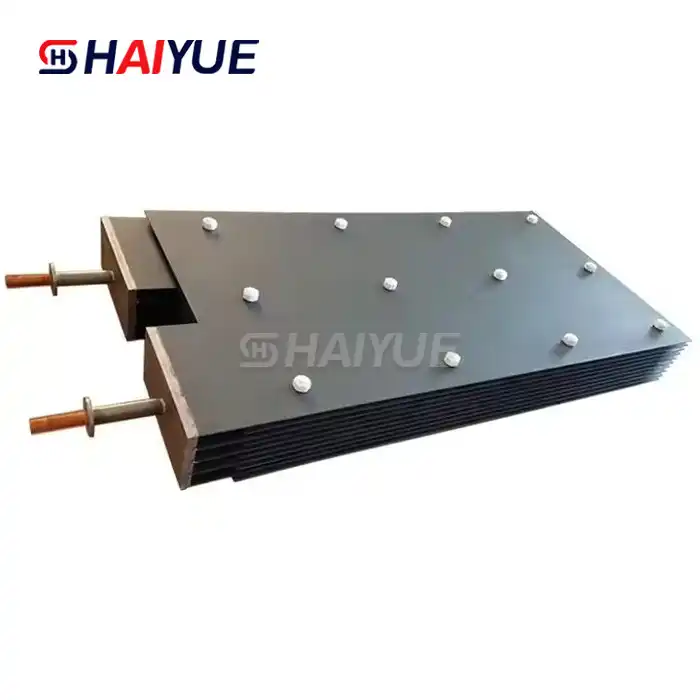

Coating: MMO coatings to enhance the anode's resistance to corrosive black liquor and extend its operational life.

Size: Custom sizes to meet the needs of specific papermaking treatment systems.

Surface Treatment: Acid cleaning, sand blasting, and polished finishes for better electrochemical activity and reduced maintenance.

Production time: 15 working days, with expedited manufacturing available if required.

Product Introduction

A Titanium Anode for Treating Papermaking Black Liquor is a vital component used in the electrochemical treatment of papermaking wastewater, especially black liquor, a by-product of the pulping process. These anodes are used in the electrolysis process to break down harmful compounds, improve water quality, and make the recycling of papermaking black liquor more efficient. Titanium, known for its excellent corrosion resistance and high strength-to-weight ratio, is the perfect material for these anodes, ensuring a long service life and consistent performance.

Technical Specifications

| Specification | Value |

|---|---|

| Material | Titanium (Grade 1 or Grade 2) |

| Surface Coating | Ruthenium Oxide or Mixed Metal Oxide (MMO) |

| Thickness | 1 mm to 5 mm |

| Dimensions | Customizable based on client specifications |

| Voltage | 3V to 10V |

| Current Density | 200-500 A/m² |

| Property | Description |

|---|---|

| Corrosion Resistance | Excellent in acidic and alkaline environments |

| Service Life | 5-10 years (depending on operational conditions) |

| Operating Temperature | Up to 80°C |

| Electrical Conductivity | High |

| Manufacturing Standard | ASTM B265, ASTM F67 |

| Application | Value |

|---|---|

| Industry | Papermaking, Water Treatment |

| Usage | Electrochemical Treatment of Black Liquor |

| Function | Wastewater Treatment, Chemical Degradation |

|

|

|

|

|

|

|

|

Product Features (Key Features)

- Superior Corrosion Resistance: Titanium is highly resistant to the aggressive chemical environment of papermaking black liquor, ensuring longevity and reduced maintenance costs.

- High Strength-to-Weight Ratio: Titanium anodes are both strong and lightweight, making them suitable for large-scale industrial applications.

- Customizable Sizes: We provide customizable anodes tailored to your specific requirements, whether you need small units or large-scale systems.

- Energy Efficient: Titanium anodes help in reducing energy consumption during the treatment process, lowering operational costs.

- Sustainability: By improving the efficiency of wastewater treatment, these anodes contribute to reducing environmental impact, aligning with global sustainability goals.

Applications

- Papermaking Industry: Used in the treatment of black liquor, ensuring cleaner and more sustainable wastewater management.

- Water Treatment: Ideal for other applications in industrial water treatment where corrosion resistance is key.

- Chemical Processing: Effective in reducing chemical pollution and enhancing the purification of wastewater.

Manufacturing Process

Our titanium anodes are produced using state-of-the-art equipment, including CNC machining, plasma arc welding, and advanced heat treatment processes. The process begins with the selection of high-purity titanium, followed by coating with ruthenium oxide or MMO to enhance electrical conductivity and corrosion resistance. Each anode undergoes rigorous quality checks to ensure consistency and superior performance before it is shipped.

Quality Assurance

At Baoji Haiyue, we adhere to the highest industry standards, including ISO9001:2015, AS9100D, and GJB9001C:2007 certifications. Our anodes are tested using advanced methods like ultrasonic testing, eddy current testing, and spectral analysis to ensure they meet or exceed the required performance specifications. With these stringent quality checks, we guarantee reliable, high-quality products that will support your operations for years to come.

Packaging and Logistics

We offer secure, well-packaged shipments to ensure that our products reach you in optimal condition. Our packaging includes anti-corrosion protection to maintain the integrity of the titanium anodes. We handle global shipments with fast delivery options, and our experienced logistics team ensures timely arrivals no matter where you are located.

Customer Support

We pride ourselves on offering excellent customer service. Whether you need pre-sale consultations or post-sale support, our team is always ready to assist you. From technical guidance on the application of titanium anodes to troubleshooting operational issues, we provide the expertise you need to maximize the performance of your equipment.

Why Choose Us?

- Complete Product Range: We offer a full range of titanium anodes and custom solutions for various industrial applications.

- One-Stop Solution: From manufacturing to delivery, we provide end-to-end service, ensuring a seamless customer experience.

- Global Reach: With a presence in over 20 countries, we provide reliable service to clients worldwide.

- Fast Delivery: Our streamlined manufacturing and logistics systems ensure prompt delivery.

- Timely Global After-Sales Service: We offer local support to ensure minimal downtime and maximum performance.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We understand that every business has unique requirements. Our OEM services allow us to provide customized titanium anodes for your specific needs. Whether it's size, coating, or performance specifications, we work with you to create a solution tailored to your exact requirements.

Frequently Asked Questions (FAQs)

1. What is the lifespan of titanium anodes for treating papermaking black liquor?

Titanium anodes typically last between 5 to 10 years, depending on the conditions of use, such as voltage and temperature.

2. Are your titanium anodes customizable?

Yes, we offer customizable sizes, coatings, and specifications to suit your particular application.

3. How do I maintain titanium anodes?

Titanium anodes require minimal maintenance. Regular inspections are recommended to ensure their optimal performance and longevity.

4. Can I get a quote for large orders?

Absolutely! Please contact us directly, and we'll provide a competitive quote based on your order volume and specifications.

Contact Details

- Direct Contact: Jolina@bjhyti.com

- Phone Number: +86-18392721678

Learn about our latest products and discounts through SMS or email

_1739946255322.webp)

_1740453413527.webp)

_1739001750296.webp)