- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

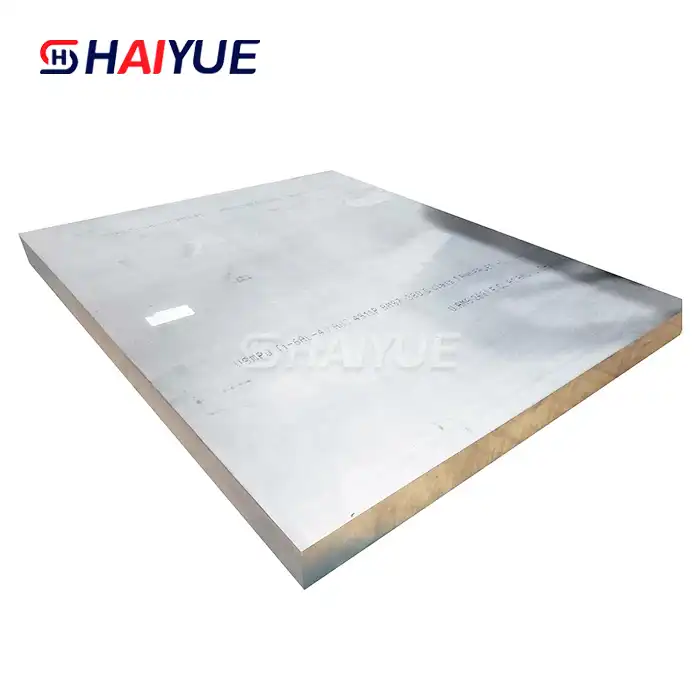

titanium grade 5 plates

2.Lightweight design, perfect for aerospace and marine industries.

3.Superior surface finish for reliable industrial applications.

4.Excellent weldability and formability for custom projects.

5.Precision thickness control ensures consistent performance.

Titanium Grade 5 Plates – High-Performance Material for Critical Applications

Product Introduction

Titanium Grade 5 plates, also known as Ti-6Al-4V, are one of the most commonly used titanium alloys in industries that demand high strength, lightweight properties, and excellent corrosion resistance. This alloy consists of 90% titanium, 6% aluminum, and 4% vanadium, combining the best features of both strength and durability. Known for its high tensile strength, low density, and resistance to oxidation, Titanium Grade 5 is a preferred choice for applications ranging from aerospace to medical devices.

At Baoji Haiyue New Metal Materials Co., Ltd., we offer premium Titanium Grade 5 plates designed to meet rigorous industry standards and exceed customer expectations. Whether you need a standard size or a custom specification, our plates are produced with precision and guaranteed to deliver superior performance in extreme environments.

Technical Specifications

| Property | Value | Unit |

|---|---|---|

| Density | 4.43 | g/cm³ |

| Tensile Strength | 900–1,100 | MPa |

| Yield Strength | 850 | MPa |

| Elongation at Break | 10–15 | % |

| Hardness | 330–370 | Vickers HV |

| Modulus of Elasticity | 113,800 | MPa |

| Thermal Conductivity | 7.3 | W/m·K |

| Melting Point | 1,668 | °C |

| Heat Treatment | Solution-treated and aged | |

| Standard Dimensions | Thickness: 2 mm to 100 mm, Width: Custom | mm |

Grades and Standards:

- U.S. Standard: ASTM B265, AMS 4911, AMS 4967

- Russian Standard: GOST 19807-2001, GOST 19808-2001

- Japanese Standard: JIS H 4600:2014, JIS H 4610:2014

|

|

|

|

|

|

|

|

Product Features (Key Features)

- Lightweight and Strong: Titanium Grade 5 plates offer excellent strength-to-weight ratios, making them ideal for applications that require high performance without the added weight.

- Corrosion Resistance: Titanium’s natural resistance to corrosion ensures durability in aggressive environments, such as marine and chemical processing industries.

- Biocompatibility: With its ability to resist oxidation and not react with body fluids, Titanium Grade 5 is often used in medical implants and surgical instruments.

- Customizability: We offer tailored sizes and finishes to meet specific customer requirements, whether you need thin plates for intricate components or thicker plates for structural parts.

- High Temperature Stability: The material maintains its strength even at elevated temperatures, making it ideal for aerospace and automotive applications.

Applications

Titanium Grade 5 plates are widely used across several industries, including:

- Aerospace & Aviation: For lightweight, high-strength components in aircraft and spacecraft, such as structural parts, turbine engines, and fasteners.

- Medical Devices: Used for implants, prosthetics, and surgical tools, where biocompatibility and corrosion resistance are crucial.

- Chemical Processing: For manufacturing reactors, heat exchangers, and piping systems resistant to aggressive chemicals.

- Energy Sector: In nuclear, solar, and wind energy systems, as well as components for power plants.

- Marine Engineering: Ideal for shipbuilding and offshore platforms, where resistance to saltwater corrosion is essential.

- Industrial Manufacturing: Used in tools, fasteners, and various machinery components that require durability and reliability.

Manufacturing Process

Our Titanium Grade 5 plates are manufactured through a rigorous process to ensure consistency and high performance:

- Material Selection: We source premium-grade titanium alloys that comply with ASTM, AMS, and other international standards.

- Forging: The titanium ingot is forged into billets, which are then processed further.

- Rolling & Annealing: The billets are rolled into flat plates and annealed to enhance mechanical properties.

- CNC Machining: Plates are precision-cut using CNC machinery to meet custom specifications.

- Surface Treatment: Plates undergo surface treatment processes such as pickling, sandblasting, or coating to ensure durability and resistance to corrosion.

Quality Assurance

Quality is at the forefront of our operations. Each batch of Titanium Grade 5 plates undergoes rigorous testing and inspection, ensuring compliance with global industry standards. Our quality assurance processes include:

- Ultrasonic Testing: To detect internal flaws and ensure material integrity.

- Spectral Analysis: To verify the composition of the titanium alloy.

- Hardness Testing: To ensure the plates meet the required strength specifications.

- Dimensional Inspection: To confirm that the plates meet customer size and tolerance requirements.

Packaging and Logistics

We ensure that our Titanium Grade 5 plates are packaged securely for transit. Depending on the size and quantity, we use:

- Standard Packaging: Plastic wrap, wooden crates, or custom packaging for smaller orders.

- Heavy Duty Packaging: For larger orders, plates are securely wrapped in heavy-duty packaging, ensuring they remain in pristine condition during transport.

Our global logistics network ensures that your order will be delivered on time, whether you're located in North America, Europe, Asia-Pacific, or the Middle East.

Customer Support

At Baoji Haiyue New Metal Materials Co., Ltd., we provide unparalleled customer support. Whether you're a first-time buyer or a long-term partner, our team is available to answer questions, offer technical advice, and help you select the right materials for your project. Reach out to us via email at jolina@bjhyti.com or call +86-18392721678 for more information.

Why Choose Us?

- Complete Product Range: We offer a wide range of titanium and non-ferrous metal products, including custom specifications.

- Full-Process Production: From raw material selection to final product delivery, we control every step of the production process.

- One-Stop Solution: Baoji Haiyue is your partner for all titanium and metal needs, with a focus on quality and timely delivery.

- Global Reach: We supply to over 20 countries worldwide, ensuring that your needs are met no matter your location.

- Fast Delivery: With advanced manufacturing capabilities and a robust logistics system, we guarantee fast, on-time deliveries.

- Customer Satisfaction: We are dedicated to offering exceptional service and reliable products to keep your operations running smoothly.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We offer OEM services to meet your specific needs. Whether you require custom sizes, shapes, or unique processing methods, we work closely with you to provide tailored solutions that align with your technical requirements. Our experienced engineers and technicians ensure that each product meets the highest standards of quality and performance.

Frequently Asked Questions (FAQs)

Q1: What are the main applications of Titanium Grade 5 plates?

- Titanium Grade 5 plates are used in aerospace, medical devices, chemical processing, energy, marine engineering, and industrial manufacturing.

Q2: What is the maximum thickness available for Titanium Grade 5 plates?

- We offer Titanium Grade 5 plates with thicknesses ranging from 2 mm to 100 mm, and we can customize thickness based on your needs.

Q3: How do I know if the titanium plates meet my industry standards?

- All our products are manufactured according to international standards such as ASTM, AMS, and JIS, and undergo rigorous testing and inspection.

Q4: Can you provide customized sizes?

- Yes, we offer customized Titanium Grade 5 plates to meet your specific dimensions and requirements.

Q5: How long will it take to receive my order?

- Delivery time depends on the size and quantity of your order. Please contact us for a specific delivery timeline.

Contact Details

- Direct Contact:Jolina@bjhyti.com

- Phone Number: +86-18392721678

Learn about our latest products and discounts through SMS or email