- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Greek

- German

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

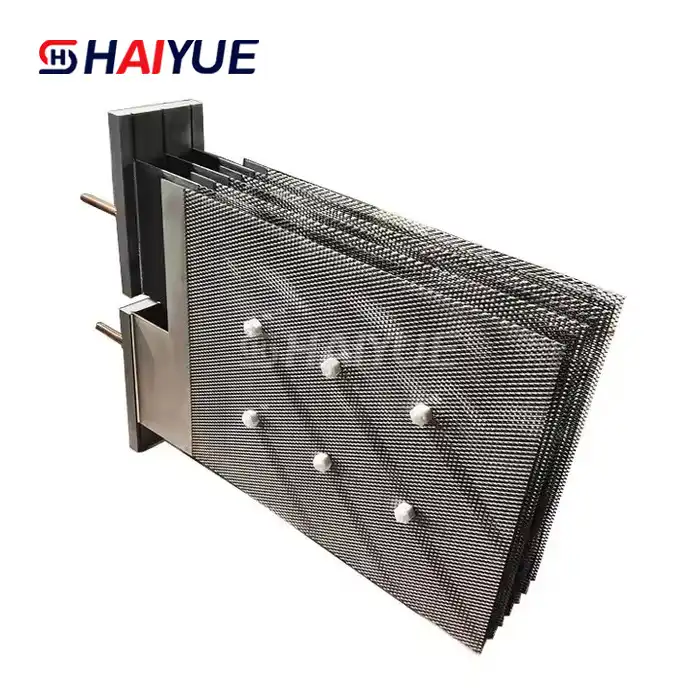

Titanium-coated ruthenium-iridium anode for chlor-alkali

Coating: Ruthenium-iridium coatings to provide superior electrochemical stability and increase the lifespan of the anode.

Size: Custom sizes available to meet specific chlor-alkali electrolysis system requirements.

Surface Treatment: Acid cleaning, sand blasting, and polished finishes for optimal electrochemical efficiency and durability.

Production time: 15 working days, with expedited options available.

Product Introduction

The Titanium-coated Ruthenium-Iridium Anode for Chlor-Alkali is an advanced, high-efficiency electrode designed for use in electrochemical processes, particularly in chlor-alkali production. These electrodes combine the superior strength of titanium with the corrosion resistance and conductivity of ruthenium and iridium, offering long-lasting performance in harsh chemical environments. This product is ideal for industries such as chemical processing, energy, and environmental applications, where reliability and longevity are essential.

Technical Specifications

| Feature | Specification |

|---|---|

| Material | Titanium (base), Ruthenium, Iridium |

| Coating Thickness | 10-50 microns |

| Voltage Rating | Up to 5V |

| Temperature Resistance | 300°C to 450°C |

| Chlorine Resistance | Excellent |

| Current Efficiency | 95-98% |

| Service Life | 10-15 years |

|

|

|

|

|

|

Product Features

- Corrosion Resistance: The ruthenium-iridium coating provides exceptional resistance to corrosion in highly acidic and chlorine-rich environments, ensuring extended service life even under harsh operating conditions.

- High Conductivity: Enhanced conductivity allows for superior electrochemical efficiency, reducing energy consumption and improving production performance.

- Customizable: Available in various sizes and configurations to meet specific operational requirements.

- Durability: The titanium base provides unmatched mechanical strength, while the coating ensures protection from electrochemical degradation.

- Cost-Efficiency: Reduced need for frequent replacements, leading to lower maintenance costs over time.

Applications

- Chlor-Alkali Industry: Used in electrolysis for the production of chlorine, sodium hydroxide, and potassium hydroxide.

- Water Treatment: Ideal for electrolytic disinfection systems.

- Chemical Processing: Suitable for processes involving harsh chemicals and electrolytic reactions.

- Energy: Effective in energy storage and conversion systems requiring long-lasting electrodes.

Manufacturing Process

The Titanium-coated Ruthenium-Iridium Anode for Chlor-Alkali undergoes a rigorous manufacturing process, ensuring high quality and reliability. This includes:

- Titanium Substrate Preparation: High-purity titanium is cleaned and pretreated for coating.

- Electrode Coating: Ruthenium and iridium are carefully applied to the titanium substrate using advanced sputtering or thermal spraying techniques.

- Heat Treatment: The coated anodes are subjected to heat treatment to enhance adhesion and performance.

- Quality Control: Each anode undergoes strict quality tests, including ultrasonic and visual inspections, to ensure compliance with international standards.

Quality Assurance

We are committed to providing products that meet the highest industry standards. The Titanium-coated Ruthenium-Iridium Anode for Chlor-Alkali is manufactured under ISO9001:2015 and other relevant quality management systems. Each batch undergoes rigorous testing to ensure durability, performance, and compliance with customer specifications.

Packaging and Logistics

Our electrodes are securely packaged to prevent damage during shipping. The packaging is designed to ensure that the products reach customers in perfect condition. We offer global shipping options, including air, sea, and land transport, with timely delivery services. Packaging is tailored to the specific needs of the customer, ensuring ease of handling and storage.

Customer Support

Our dedicated support team is available to assist with product inquiries, technical specifications, and after-sales service. Whether you need help with installation or have questions about the product's performance, we are here to provide expert guidance and support.

Why Choose Us

- Complete Product Range: Baoji Haiyue offers a comprehensive range of titanium and metal products, including customized solutions.

- One-Stop Solution: From manufacturing to delivery, we provide end-to-end services for all your titanium and anode needs.

- Global Reach: We have a global customer base and an extensive sales and service network in over 20 countries.

- Fast Delivery & Competitive Pricing: Our efficient production processes and international logistics network ensure quick turnaround times and competitive prices.

- Expert Support: Our team of engineers and technicians is always available to provide technical advice and customer support.

- Sustainability: We are committed to eco-friendly practices, reducing our environmental impact through green manufacturing techniques.

Development History

Company founded in Baoji, "Titanium Valley," specializing in titanium and non-ferrous metals.

Expanded product range to include zirconium, tantalum, nickel, tungsten, and molybdenum products.

Achieved ISO9001:2015 certification, ensuring high-quality production standards.

Upgraded manufacturing facilities, adding VAR furnaces, CNC machinery, and advanced heat treatment systems.

Expanded global presence, establishing partnerships in the United States, Germany, and South Korea.

Obtained AS9100D certification for aerospace industry compliance and advanced product quality.

Introduced customized solutions for the aerospace, medical, and energy industries, enhancing global reach.

Celebrated 14 years of excellence with over 2,000 tons of annual titanium production capacity.

Product Quality Management

Production and Processing

Workshop and Equipment

Packaging

Main Products

Applied Industries

Be used in a wide range of industries.

Electrolytic copper foil manufacturing industry

Hydrometallurgy industry

Sewage treatment industry

Cyclone electrolysis industry

Etching liquid electrolysis recovery industry

Electrolytic sodium hypochlorite industry

OEM Services

We offer customized solutions to meet the specific needs of your business. Whether you require unique sizes, coatings, or configurations, we can tailor our products to your exact specifications. Our flexible manufacturing capabilities allow us to handle large orders, ensuring that we meet the demands of your production schedule.

Frequently Asked Questions (FAQs)

Q1: What is the maximum temperature the anode can withstand?

A1: The Titanium-coated Ruthenium-Iridium Anode can operate at temperatures between 300°C to 450°C, making it ideal for high-temperature electrochemical processes.

Q2: How long does the anode typically last?

A2: The anode has a service life of 10-15 years, depending on the operational conditions and maintenance.

Q3: Can I customize the size of the anodes?

A3: Yes, we offer customized sizes and coatings based on your specific requirements.

Q4: Is there any warranty on the anode?

A4: Yes, we offer a warranty on all our products, ensuring their performance and reliability under normal operating conditions.

Q5: What industries can benefit from these anodes?

A5: These anodes are primarily used in the chlor-alkali industry but are also suitable for chemical processing, energy, and water treatment sectors.

Contact Details

For more information or a quote, please contact:

Email: Jolina@bjhyti.com

Phone: +86-18392721678

Learn about our latest products and discounts through SMS or email

_1739168266637.webp)